Isitatimende Sobumfihlo: Ubumfihlo bakho bubaluleke kakhulu kithina. Inkampani yethu ithembisa ukungadaluli imininingwane yakho kunoma yikuphi ukuveza izimvume zakho ezicacile.

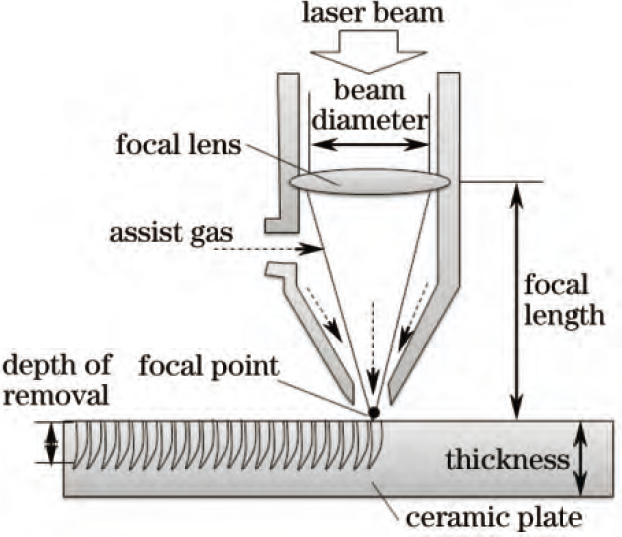

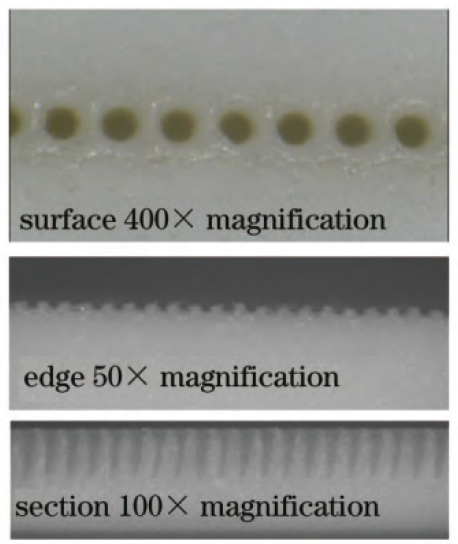

I-Advanced Cerafic Plate H aqhakaza izinzuzo zezakhiwo ezivelele zokufakwa kukagesi, izici ezinhle kakhulu eziphakeme kakhulu, ukuvumelanisa okuhle okushisayo, isilinganiso sokunwebeka, ukuhambisana nezinto ezahlukahlukene ze-elekthronikhi, kanye nezinto ezizinzile zamakhemikhali. Zisetshenziswa kabanzi emkhakheni wezigatshana. I-Alumina ceramics ingenye ye-ceramics esetshenziswa kabanzi manje. Ngokwenza ngcono ukunemba okusebenzayo kanye nokusebenza kahle kwe-Alumina Ceramic Subrestrate, izindlela zokulungiswa kwemishini zendabuko ngeke zisakwazi ukufeza izidingo. Ubuchwepheshe be-Laser Ukucubungula bunezinzuzo zokungalandeli, ukuguquguquka, ukusebenza kahle okuphezulu, ukulawulwa okulula kwedijithali, nokunemba okuphezulu, futhi sekuyinye yezindlela ezinhle kakhulu zokucubungula ama-ceramic namuhla.Umbhali we-laser ubizwa nangokuthi ukusika kwesigaba noma ukusika okulawulwayo kokukhubazeka. Umshini wokuthi i-laser beam igxile ebusweni be-alumina ceramic substrate ngohlelo lokukhanya okukhanyayo, futhi ukusabela okuphezulu kwenzeka ukukhiqiza izinga lokushisa eliphakeme, ukuvala, ukuncibilikisa kanye nokushintshana kwendawo ye-ceramic screed. Umphezulu we-Ceramic wenza izimbobo eziyimpumputhe (ama-grooves) axhumana. Uma ukucindezelwa kusetshenziswa eceleni kwendawo yombhali, ngenxa yokuxineka kwengcindezi, okuqukethwe kuphulwe kalula emgqeni ulayini oqondile ukuze uqedele ukushelela.

Emikhakheni ye-laser ye-alumina ceramics, emkhakheni wokusika okuphansi kanye nokudla, ama-co2 lasers kanye nama-laser we-fiber kulula ukuzuza amandla aphezulu, ashibhile, futhi athola izindleko zokulungisa kanye nokulungiswa okuqhathaniswa nezinhlobo zama-lasers. I-Alumina ceramics inokubukeka okuphezulu kakhulu (ngenhla kwama-80%) kuma-co2 lasers nge-wavelength ka-10.6 mm, okwenza ama-CO2 ama-lasers asetshenziswe kabanzi ekusebenzeni kwama-alumina ceramic substrates. Kodwa-ke, lapho i-CO2 Lasers Process Subrestrates ye-Ceramic, indawo egxile yimikhulu, ekhawulela ukunemba kwemishini. Ngokuphambene nalokho, ukucubungulwa kwe-weser ye-ceramic subser ye-ceramic ivumela indawo encane egxile egxile, ububanzi be-inform Brik

I-alumina ceramic substrate inokuthambekela okuphezulu kwesibani se-laser eduze kwe-wavelength ka-1.06 mm, edlula ama-80%, okuvame ukuholela ezinkingeni ezinjengamaphuzu aphukile, imigqa yokusika engahambisani ngesikhathi sokucutshungulwa. Usebenzisa izici zamandla aphezulu aphezulu kanye namandla aphezulu we-pulse ye-qcw ye-fiber laser, ukusika kanye nokubhalwa kwama-96% ama-alumina ceramic substrates ngobukhulu obungu-1 mm ngokusebenzisa igesi ebalulekile ngaphandle kwesidingo sokufaka isicelo se-ceramic Ingaphezulu, yenza lula inqubo yezobuchwepheshe futhi inciphise izindleko zokucubungula.

LET'S GET IN TOUCH

Isitatimende Sobumfihlo: Ubumfihlo bakho bubaluleke kakhulu kithina. Inkampani yethu ithembisa ukungadaluli imininingwane yakho kunoma yikuphi ukuveza izimvume zakho ezicacile.

Gcwalisa eminye imininingwane ukuze ukwazi ukuxhumana nawe ngokushesha

Isitatimende Sobumfihlo: Ubumfihlo bakho bubaluleke kakhulu kithina. Inkampani yethu ithembisa ukungadaluli imininingwane yakho kunoma yikuphi ukuveza izimvume zakho ezicacile.