Isitatimende Sobumfihlo: Ubumfihlo bakho bubaluleke kakhulu kithina. Inkampani yethu ithembisa ukungadaluli imininingwane yakho kunoma yikuphi ukuveza izimvume zakho ezicacile.

Ngenqubekela phambili kanye nentuthuko yezobuchwepheshe, izinga lokushisa lamanje, lokusebenza kanye nemvamisa kumadivayisi bekulokhu kuphakama kancane kancane. Ukuze uhlangabezane nokwethenjwa kwamadivayisi namasekethe, izidingo eziphakeme zibekwe phambili kubathwali be-chip. I-Ceramic substrates isetshenziswa kabanzi kulezi zinkambu ngenxa yezakhiwo zazo ezinhle kakhulu ezishisayo, izakhiwo ze-microwave, izakhiwo zemishini kanye nokwethenjwa okuphezulu.

Njengamanje, izinto eziphambili ze-ceramic ezisetshenziswe kuma-ceramic substrates yilezi: alumina (al2o3), i-aluminum nitride (i-aluminum nitride (i-silicon nitride (i-silicon carbide (i-silicon Carbide (i-SIC) ne -beryllium oxide (beo).

okushisayo (W / KM) kwensimu okuphazamisayo okuphazamisayo (KV / mm ^ (- 1)) I-powder enobuthi kakhulu, umkhawulo wokusebenzisa 100.40.40 Ma Terial Ukuhlanzeka okushisayo Ama-Fomme amafushane we -NT s Al2o3 99% 29 9.7 10 Ukusebenza kwezindleko okuhle kakhulu,

Izicelo eziningi ezibanziALN 99% 150 8.9 Ukusebenza okuphezulu ,

Kepha kubiza kakhului-beo I-99% 310 6.4 10 SI3N4 99% 106 9.4 100 100.40 % 270 40 0.7 Finyelela izinhlelo zokusebenza ezivame kakhulu

Ake sibheke izici ezimfishane zalawa ma-ceramics ama-5 athuthukile ezigatshana ezilandelayo:

1. I-Alumina (Al2o3)

I-Al2o3 Hologenous Polycrystals ingafinyelela ngaphezu kwezinhlobo eziyi-10, futhi izinhlobo eziphambili zekristalu zimi ngokulandelayo: α-al2o3, γ-al2o3 ne-Zta-Al2o3 neZta-Al2o3 neZta-Al2o3 neZta-Al2o3 neZta-Al2o3 neZta-Al2o3 neZta-Al2o3 neZta-Al2o3 neZta-Al2o3 naseZta-Al2o3 naseZta-Al2o3 naseZta-Al2o3 naseZta-Al2o3 naseZta-Al2o3 naseZta-Al2o3 naseZta-Al2o3 neZta-Al2o3. Phakathi kwazo, i-α-al2o3 inomsebenzi ophansi kakhulu futhi izinzile kakhulu phakathi kwamafomu amane aphambili ekristalu, kanti iseli yalo leyunithi liyi-rhombohedron ekhonjiwe, elingohlelo lwe-hexagonal crystal system. Isakhiwo se-α-al2o3 siqinile, isakhiwo se-Corundum, singaba khona impela kuwo wonke amazinga okushisa; Lapho amazinga okushisa efinyelela ku-1000 ~ 1600 ° C, okunye ukuhlukahluka kuzoguqukela ngokungenakuphikiswa kube yi-α-al2o3.

2. I-Aluminium Nitride (ALN)

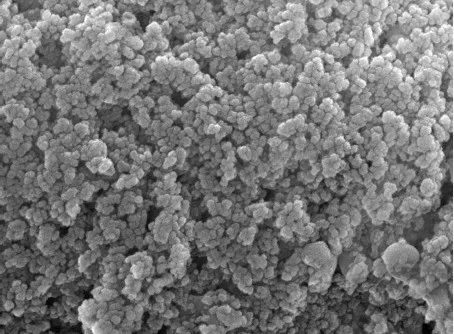

I-ALN uhlobo lweqembu ⅲ-v luhlanganisiwe ngesakhiwo seWortzite. Iseli yayo yeyunithi i-ALN4 Tetrahedron, okungoluhlelo lwe-Hexagonal Crystal futhi inesibopho esiqinile se-Combared, ngakho-ke inezakhiwo ezinhle kakhulu zemishini kanye namandla aphezulu agoba. Ngokweqiniso, inqwaba yayo ye-crystal yi-3.2611G / CM3, ngakho-ke inokuphamba okuphezulu okushisayo, futhi i-aln crystal emsulwa inokuvuselelwa kwekamelo okungu-320W / (m · I-substrate ingafinyelela ku-150w / (m · k), okungamahlandla angaphezu kwezi-5 e-Al2o3. I-coefficion ebabazekayo ye-Thermal

Umdwebo 2: I-Powder of Aluminium NITride

3. Silicon nitride (si3n4)

I-SI2N4 i-collally isibopho esihlanganisiwe nezinhlaka ezintathu zekristali: α-si3n4, β-si3n4, ne-γ-si3n4. Phakathi kwazo, i-α-si3n4 ne-β-si3n4 ziyizindlela ezivame kakhulu zekristalu, nesakhiwo se-hexagonal. Ukuvuselelwa okushisayo kweCrystal Crystal Si2n4 eyodwa kungafinyelela ku-400W / (m · k). Kodwa-ke, ngenxa yokudluliswa kokushisa kwe-phonon, kunezihlahla zokushisa ezifana nezikhala kanye nokungezelwa kwelinye izwe, futhi ukungcola kubangela ukuthi uPhonon ahlakaze ukwanda, ngakho-ke ukuthuthuka kwama-ceramics kwangempela kuma-20W / (m · k) . Ngokwenza kahle inqubo yokulingana kanye nenqubo yesono, ukuvumelanisa okushisayo kufinyelele ku-106W / (m · k). I-coefficion ethe xaxa ye-SI2N4 ye-SI2N4 imayelana ne-3.0 × 10-6 / c, okuhambisana kahle nezinto zokwakha ze-SI, ezizwakala kahle, okwenza i-sei3n4 ceramics ibe yinto ekhangayo ye-ceramic substrate impahla yamadivayisi aphezulu we-armal acleakinic electronic.

I-4.Silicon Carbide (Sic)

I-Single Crystal Sic yaziwa njengesizukulwane sesithathu semiconductor, esinezinzuzo ze-Band Gap enkulu, i-High Breakdown Voltage, Ukusebenza okuphezulu okushisayo kanye nesivinini esikhulu se-elektroni.

Ngokungeza inani elincane le-beo kanye ne-b2o3 ku-sic ukwandisa ukumelana kwalo, bese ungeza izithasiselo ezihambisanayo zokushisa ngenhla ngaphezulu kwe-1900 ℃ usebenzisa ububanzi obungaphezulu kwama-arvemics. Ukuvuselelwa okushisayo kwe-ceramics ye-spic ngobumsulwa obuhlukile obulungiselelwe izindlela ezahlukahlukene ze-sonsoring kanye nezithasiselo zingu-100 ~ 490w / (m · k) emazingeni okushisa asekamelweni. Ngoba i-dielectric ihlala njalo ye-ceramics i-ceramics inkulu kakhulu, ilungele izinhlelo zokusebenza ezivame kakhulu, futhi ayilungele izinhlelo zokusebenza ezivame kakhulu.

5. Beryllia (beo)

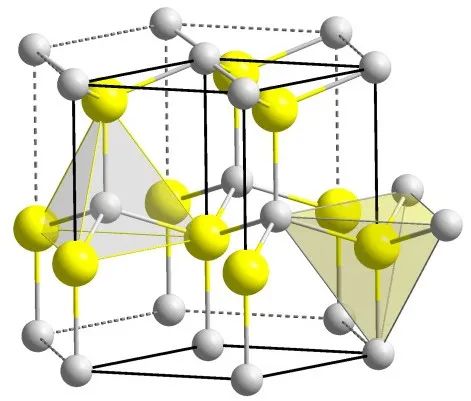

I-beo yisakhiwo seWartzite kanye neseli uhlelo lwe-cubic crystal. Ukuqhutshwa kwalo okushisayo kuphezulu kakhulu, i-Beo Mass Fraction yama-ceramics angama-99%, emazingeni okushisa akhona, ukuqhutshwa kwayo okushisayo (Ukuvuselelwa okushisayo) kungafinyelela ama-310W / (m · Hhayi kuphela inomthamo wokudlulisa ukushisa okuphezulu kakhulu, kepha futhi ilahlekelwe yi-dielectric i-dielectric ihlala njalo kanye nokufakelwa okuphezulu kanye nempahla emishini, ama-ceramics ama-beos yizinto ezikhethiwe ekusetshenzisweni kwamadivaysi aphezulu namasekethe adinga ukuvumelanisa okuphezulu.

Umdwebo 5: Ukwakheka kwe-crystal ye-beryllia

Njengamanje, izinto ezivame ukusetshenziswa kwe-ceramic substrate eChina ikakhulukazi ziyi-al2o3, i-ALN ne-SI2N4. I-ceramic substrate eyenziwe ngobuchwepheshe be-LTCC ingahlanganisa izingxenye ezingenamikhawulo njengabaphikisayo, ama-capacitors kanye ne-inductors esakhiweni esinezinhlangothi ezintathu. Ngokuphikisana nokuhlanganiswa kwama-semiconductors, okuyizinto ezisebenzayo ngokuyinhloko, i-LTCC inamakhono aphezulu we-3D ukuxhumanisa ama-wiring.

LET'S GET IN TOUCH

Isitatimende Sobumfihlo: Ubumfihlo bakho bubaluleke kakhulu kithina. Inkampani yethu ithembisa ukungadaluli imininingwane yakho kunoma yikuphi ukuveza izimvume zakho ezicacile.

Gcwalisa eminye imininingwane ukuze ukwazi ukuxhumana nawe ngokushesha

Isitatimende Sobumfihlo: Ubumfihlo bakho bubaluleke kakhulu kithina. Inkampani yethu ithembisa ukungadaluli imininingwane yakho kunoma yikuphi ukuveza izimvume zakho ezicacile.