Isitatimende Sobumfihlo: Ubumfihlo bakho bubaluleke kakhulu kithina. Inkampani yethu ithembisa ukungadaluli imininingwane yakho kunoma yikuphi ukuveza izimvume zakho ezicacile.

Njengamanje, ukuhlolwa okuyinhloko kwesembozo esiqediwe se-ceramic sembozo, ukuhlolwa kwezindawo okubonakalayo, ukuhlolwa kwezindawo ezishisayo, ukuhlolwa kwezindawo zikagesi, ukuhlolwa kokusebenza (ukusebenza okusebenzayo) nokuhlola ukuthembeka.

Ukuhlolwa kokubukeka kwezindawo zobumba ze-ceramic kuqhutshwa njalo nge-microscopy ebonakalayo noma ebonakalayo, ikakhulukazi kufaka phakathi imifantu, izimbobo, imihuzuko ebusweni bengqimba yensimbi, ukukhonkotha, amabala nezinye iziphene zekhwalithi. Ngaphezu kwalokho, usayizi ongaphandle we-substrates, ubukhulu bengqimba yensimbi, i-warpage (camber) yezigatshana, kanye nokunemba okucacile kwendawo engezansi ye-substrate kuyadingeka ukuze kuhlolwe. Ikakhulu ukusetshenziswa kwe-flip-chip bonding, ukufakwa kwezimali okuphezulu, i-warpage engaphezulu imvamisa iyadingeka ukuba ngaphansi kwe-0,3% yobukhulu.

Eminyakeni yamuva nje, ukuthuthukiswa okuqhubekayo kobuchwepheshe bekhompyutha kanye nobuchwepheshe bokucutshungulwa kwezithombe, izindleko zokukhiqiza ziyaqhubeka nokukhuphuka, cishe bonke abakhiqizi bakhokha ngokwengeziwe ukusetshenziswa kwezobuchwepheshe bokufakelwa kanye nokuthuthukiswa komkhakha wokwakha , kanye nezindlela zokutholwa nemishini esekelwe embonweni womshini ziba njalo ngezindlela ezibalulekile zokuthuthukisa ikhwalithi yomkhiqizo futhi zithuthukise isivuno. Ngakho-ke, ukusetshenziswa kwemishini yokuhlola ukubonwa komshini ekutholweni kwe-ceramic substrate kungathuthukisa ukusebenza kahle nokunciphisa izindleko zabasebenzi ngokufanele.

Izakhiwo zemishini ze-ceramic substrate ikakhulu zibhekisela kubutho bobusuku bengqimba yensimbi yensimbi, ekhombisa amandla okubopha phakathi kwesendlalelo sensimbi kanye ne-ceramic substrate, okunquma ngqo ikhwalithi yephakeji yedivayisi elandelayo (amandla aqinile nokwethembeka, njll.) . Amandla eBonding of Ceramic Substrates alungiselelwe izindlela ezahlukahlukene ahluke kakhulu, futhi ama-plarar ceramic ama-ceramic alungiselelwe yinqubo yokushisa ephezulu (njenge-TPC, i-DBC, njll. Amandla eBonding aphezulu. Esikhathini sokufakwa kwe-ceramic okulungiselelwe yinqubo yokushisa ephansi (efana ne-DPC substrate), i-van der Waals Force kanye ne-mehermail amabutho amabutho phakathi kwengqimba yensimbi kanye ne-ceramic substrate ikakhulukazi, futhi amandla abophayo aphansi.

Izindlela zokuhlola zamandla we-ceramic metallization ku-substrate afaka:

1) Indlela yeTipte: Iteyipu isondele ebusweni bengqimba yensimbi, futhi i-roller yerabha idluliselwe kukho ukuze isuse ama-bubble ebusweni obusebugqili. Ngemuva kwemizuzwana eyi-10, donsela i-tepi ngokungezwani kwe-perpendicular engxenyeni yensimbi, bese uvivinya ukuthi ungqimba lwensimbi lususwa engxenyeni engezansi. Indlela ye-Tape iyindlela yokuhlola efanelekayo.

2) Indlela ye-Welding Wire: khetha i-Metal Wire enobubanzi obungu-0.5mm noma i-1.0mm, i-weld ngqo engxenyeni yensimbi ye-substrate ngokuncibilika kwe-solerting, bese ulinganisa amandla okudonsa wocingo lwensimbi eceleni kwengxabano imitha.

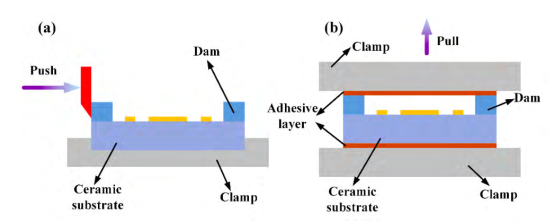

3) Indlela yama-Peel Amandla: Isendlalelo sensimbi ebusweni se-ceramic substrate tshelwa (usike) imichilo engu-5mm ~ 10mm, bese iklebhula endaweni ebheke phezulu emshinini wokuhlola ama-peel. Isivinini sokuluka siyadingeka ukuba ube ngu-50mm / min kanye nemvamisa yokulinganisa izikhathi eziyi-10 / s.

Izakhiwo ezishisayo ze-ceramic substrate ikakhulukazi zibandakanya ukusebenza kwe-thermal, ukumelana nokushisa, ukukhiqizwa kokunwebeka okushisayo kanye nokumelana okushisayo. I-Ceramic Substrate ikakhulukazi idlala indima yokuhlanza ukushisa ekuhlanganisweni kwensiza, ngakho-ke ukusebenza kwayo okushisayo kuyinkomba ebalulekile yezobuchwepheshe. Ukumelana nokushisa ikakhulu kuvivinya ukuthi ngabe i-ceramic substrate iyalwa futhi ikhubazeke emazingeni okushisa aphezulu, ngabe ungqimba lwensimbi olungaphezulu lwensimbi luhle futhi luhlanjululwe, lukhubazekile, lukhubazekile, nokuthi ingaphakathi liyahluleka yini.

Ukuvuselelwa okushisayo kwe-ceramic substrate akuhlobene nokuvuselelwa okushisayo kwe-ceramic substrate (ukumelana komzimba), kodwa futhi kuhlobene kakhulu nokuvuselelwa kwe-interface kokuqukethwe (ukuxhumana okuxhumeka okushisayo). Ngakho-ke, umhloli wokumelana we-thermal (okungakala ukumelana nomzimba okushisayo nokumelana okushisayo okushisayo kwesakhiwo esinezindlalelo eziningi) kuhlaziye ngempumelelo ukuthuthuka okushisayo kwe-ceramic substrate ye-ceramic.

Ukusebenza kukagesi kwe-ceramic substrate ikakhulukazi kusho ukuthi ungqimba lwensimbi ngaphambili nangemuva kwe-substrate kuyaqhutshwa (ngabe ikhwalithi yangaphakathi nge-hole yangaphakathi ilungile). Ngenxa yobubanzi obuncane be-hole ye-DPC ceramic substrate, kuzoba neziphambandlela ezinjenge-atter, porsity nokunye ukugcwalisa izimbobo ku-electroplating, i-X-RETER (Quelital, eshibhile ) ngokuvamile kungasetshenziselwa ukuhlola ikhwalithi yembobo ye-ceramic substrate.

Ukusebenza okuhlanganisiwe kwe-ceramic substrate ikakhulukazi kusho ukuqina kokuqina komoya nokuqina komoya (kukhawulelwe ku-ceramic substrate enezici ezintathu). Ukuze uthuthukise amandla okubopha ngocingo oluholayo, ungqimba lwensimbi ngokusebenza okuhle kwe-welding okufana ne-AU noma i-AG ngokuvamile kuvame ukuba nguwe-elendeli yensimbi ye-ceramic (ikakhulukazi i-welding pad) ukuvikela i-oxidation futhi uthuthukise ikhwalithi ebondiwe yocingo oluholayo. I-Weldomaty ngokuvamile ilinganiswa ngemishini yokufakelwa kwe-aluminium wire welding kanye namamitha wokungezwani.

I-chip ifakwe emgodini we-ceramic we-ceramic substrate, bese umgodi uvalwe ngeplate yekhava (insimbi noma ingilazi) ukubona iphakethe le-airtight ledivayisi. Ukuqina komoya kokuqukethwe kwedamu kanye nendwangu ye-welding kunquma ngokuqondile ukuqina komoya kwephakeji ledivaysi, kanye nokuqina komoya kwe-ceramic eluhlaza okwesikhashana elungiselelwe izindlela ezahlukahlukene zehlukile. I-ceramic substrate emithathu yobumbano ye-ceramic isetshenziselwa ikakhulukazi ukuvivinya ukuqina komoya kwedamu nesakhiwo, kanye nezindlela eziphambili ziyi-fluorine gas bubble kanye ne-helium mass spectrometer.

Reliability mainly tests the performance changes of ceramic substrate in a specific environment (high temperature, low temperature, high humidity, radiation, corrosion, high frequency vibration, etc.), including heat resistance, high temperature storage, high temperature cycle, thermal shock, Ukumelana nokugqwala, ukumelana nokugqwala, ukudlidliza okuthe xaxa, njll. Amasampula wehluleka angahlaziywa ngokuskena ama-elektroni microscopy (sem) kanye ne-x-ray diffractometer (XRD). Ukuskena umsindo we-microscope (sam) no-x-ray umtshina (i-X-ray) yayisetshenziselwa ukuhlaziya izindawo zokuhlaziya kanye neziphambeko.

LET'S GET IN TOUCH

Isitatimende Sobumfihlo: Ubumfihlo bakho bubaluleke kakhulu kithina. Inkampani yethu ithembisa ukungadaluli imininingwane yakho kunoma yikuphi ukuveza izimvume zakho ezicacile.

Gcwalisa eminye imininingwane ukuze ukwazi ukuxhumana nawe ngokushesha

Isitatimende Sobumfihlo: Ubumfihlo bakho bubaluleke kakhulu kithina. Inkampani yethu ithembisa ukungadaluli imininingwane yakho kunoma yikuphi ukuveza izimvume zakho ezicacile.